Our legacy is determined by what we do today.

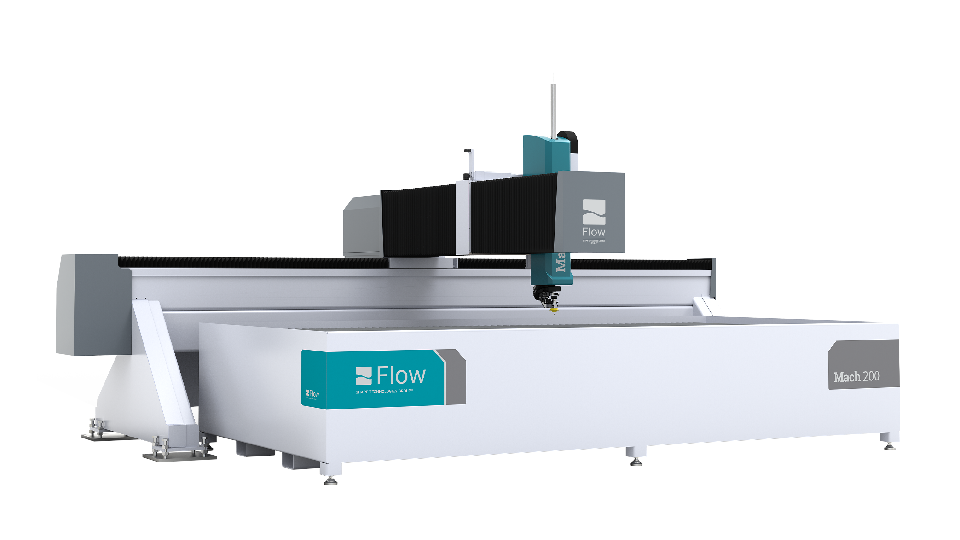

5 Axis Waterjet CNC

The Flow Mach 200 by Shape Technologies is a 5-axis, cantilever-style waterjet cutting machine designed for high-speed, high-precision, and cost-effective fabrication, particularly for materials like stone, metal, composites, and rubber.

It features advanced Pivot+™ technology for beveling and complex 3D cutting, offering capabilities of high-end, elite systems with a focus on reliability.

Key Features

-

Pivot+ 5-Axis CuttingIt is a 5-axis, 60,000 psi system designed for high-speed, accurate cutting with a repeatability of ±0.001 in (±0.025 mm).

-

Description text goes here

-

Pivot+ Cutting Head. A compact 5-axis, 60-degree beveling head that allows for taper control and high-accuracy, 3D cutting.

-

features a rapid traverse speed of 400 in/min (10 m/min) to 500 in/min (12.7 m/min) depending on the model (e.g., 200c).

-

Driven by an Omron PMAC motion controller and FlowMaster software, which allows for automatic taper, jet lag compensation, and 3D modeling.

4 Axis Mill-Turn

The DN Solutions Lynx 2600Y is a high-performance, compact CNC horizontal turning center designed for high-precision machining, featuring a 10-inch chuck, Y-axis capability, and live tooling.

It is ideal for industries like aerospace and automotive, enabling complex, single-setup operations such as milling, drilling, and tapping, reducing the need for secondary processes.

Key Features

-

Equipped with an 18 kW (24 H) motor, the main spindle provides high torque for heavy-duty cutting, with low-vibration design.

-

The ±2.95 (75 mm) Y-axis enables off-center machining, cross-drilling, and milling, eliminating the need for secondary operations.

-

BMT-65 Live Tooling Turret: A 12-station servo-driven turret allows for fast indexing (0.11 s/station) and high-speed milling up to 5,000 RPM.

-

Rapid traverse rates up to 1,417 IPM (36 m/min) minimize non-cutting time.

-

An easy-to-operate control (Fanuc), built-in, tool setter, and, user-friendly, ergonomic design.

3 Axis Machining Center

The Haas VF-1 is a widely used, entry-level vertical CNC machining center (VMC) known for its compact footprint, high accuracy, and reliability. First introduced in 1988, it was the company's "Very First One" (VF-1), offering American-made, 40-taper, 3-axis milling capabilities

The Haas VF-1 remains a staple for small-to-medium-sized shops, often serving as a foundation for production, providing reliable performance in a relatively small workspace.

Key Features

-

A 30 hp (22.4 kW) inline direct-drive spindle delivers 8,100 RPM

-

20" x 16" x 20" (508×406×508mm) travels with a 26" x 14" table holding up to 1,800 lbs.

-

20+1 position automatic tool changer (ATC) for 40-taper tools.

-

Rapid traverse rates of 1,000 ipm (inches per minute).

-

Haas CNC Control with 1 MB (standard) to 1 GB+ memory, featuring USB, Ethernet, and advanced programming capabilities.